Battery Management System (BMS): Everything you need to know about battery control

Batteries can be used for a whole range of purposes, from storing solar energy to powering electric cars and electrical appliances. Although storing electrical energy in a battery and then using it up is a straightforward process, you need a battery management system to control the flow of current efficiently for everything to run smoothly. A battery management system is an intelligent technology, usually based on software with additional hardware, enabling the battery to operate safely, efficiently and sustainably. But why is a battery management system (BMS) so important and indispensable?

Definition: What is a Battery Management System (BMS)?

A battery management system, often abbreviated to BMS, can be compared to the human central nervous system. The battery management system (BMS for batteries) is an electronic control unit that controls, monitors and optimises battery operation. Without BMS, a battery would not only be inefficient, but also unsafe in terms of overcharging, overheating and, in the worst case, explosion. Moreover, the service life and charge cycles of a battery operating without a BMS would be significantly reduced. A BMS is used in nearly all batteries, such as those found in electric vehicles, energy storage systems, portable devices, and industrial applications.

What are the functions of a Battery Management System (BMS)?

A Battery Management System typically has a multitude of duties and tasks that span a wide range of areas but always aim for efficient and safe operation.

- Battery cell monitoring: The BMS monitors the voltage, current and temperature of each battery cell at any given time. This helps make sure that all values stay within the allowed ranges and that safety isn't compromised. If these values deviate, the BMS can react and take corrective action.

- Charge and discharge control: The BMS not only monitors but also regulates the charging and discharging process. This helps prevent overcharging or extreme discharging of the battery cells and optimises the charge for the application. A controlled charge and discharge extend the battery life and ensure its safety.

- Cell balancing: A battery is made up of several cells. Each cell in a battery pack will generally have a different capacity and state of charge. These states have to be balanced. This is achieved by the BMS, which balances cell voltages so that all cells are charged and discharged evenly.

- Temperature management: It is common knowledge that a battery heats up during both charging and discharging. The BMS monitors the battery temperature (operating range: -40°C to +85°C) and, if needed, switches on cooling or heating systems to keep the battery at the right temperature. This stops it from overheating and keeps it working well.

- Safety functions: Safety risks exist wherever there is electricity, which can lead to electric shock or fire hazards. The BMS detects any faults, such as short circuits, and can then take appropriate preventive measures. This includes disconnecting the battery from the system to avoid damage.

- Data evaluation and communication: The BMS also serves as an interface for communication with other systems. Be it the vehicle control unit or chargers, a battery's BMS can send data on the battery status, state of charge, remaining capacity and any error states.

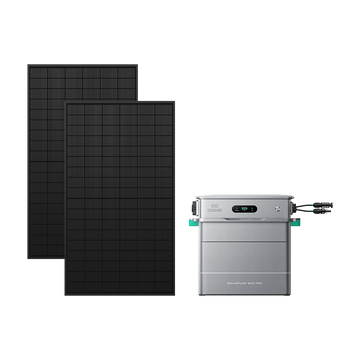

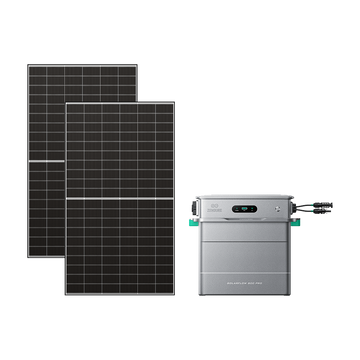

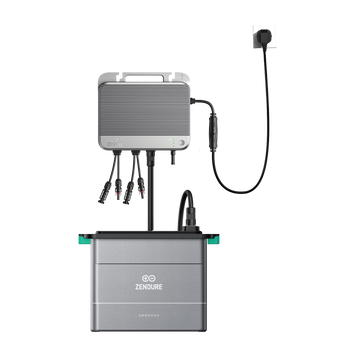

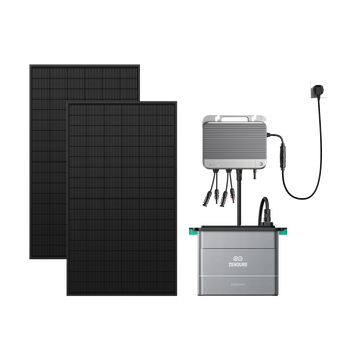

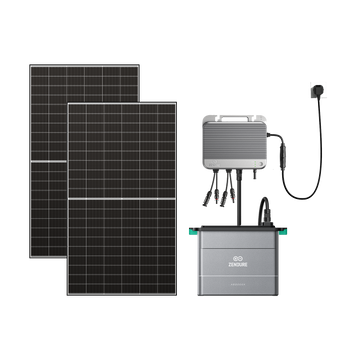

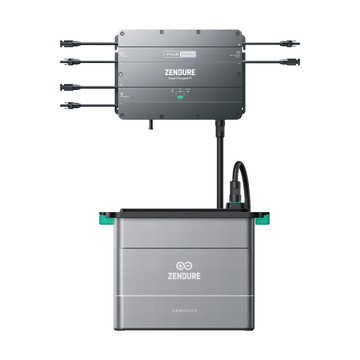

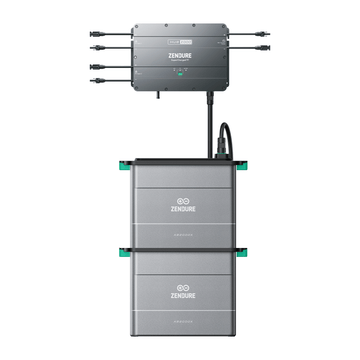

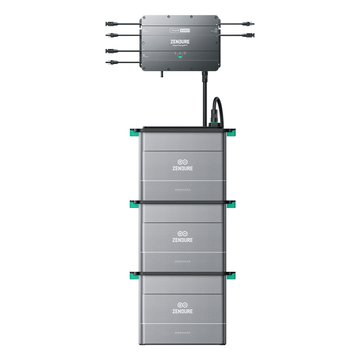

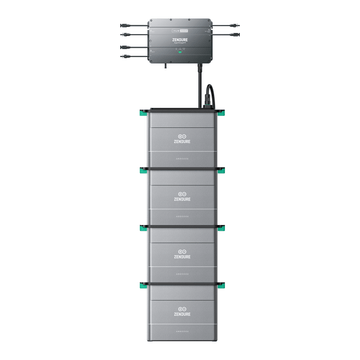

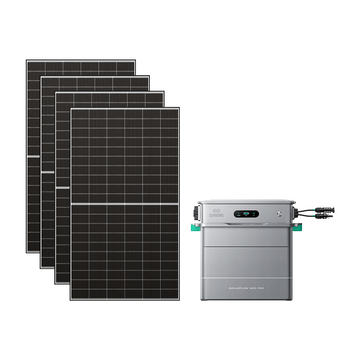

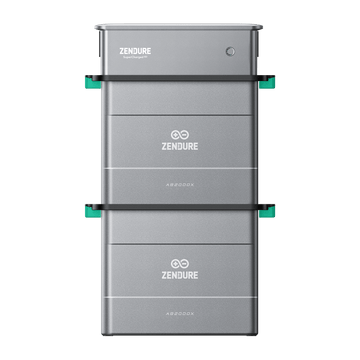

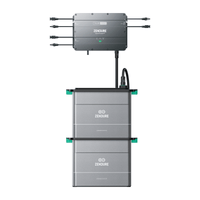

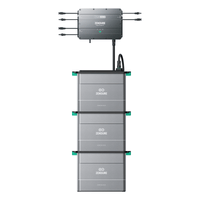

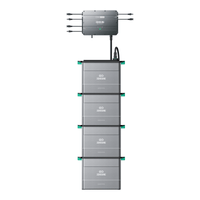

The Zendure AB2000X and AB3000X battery feature a state-of-the-art battery management system (BMS) that continuously monitors and optimises battery performance. This smart system guarantees safe and stable operation by preventing potential issues such as overheating, overcurrent, short circuits, overvoltage, and overcharging.

- Built-in aerosol fire extinguishing system;

- Smart Anti-Thermal-Runaway technology preventing overheating incidents;

- Battery-Balancing technology, preventing overcharging and overdischarging;

- Advanced battery management system;

- State-of-the-art battery self-heating technology enabling charging at -20°C in winter.

Hardware elements of a battery management system:

The battery management system is made up of both software and hardware. Where the software part is variable and can be continuously adjusted, the hardware is an integral part of a battery and is not easily replaceable. The following hardware components and sensors are usually part of a BMS:

- Voltage and current sensors: These sensors measure the voltage and current within the cells to determine their current operational status.

- Temperature sensors: These monitor the temperature to prevent overheating and consequent damage.

- Microcontroller: Comparable to the BMS's brain. This is where all data is gathered, analysed and the corresponding control commands are issued.

- Communication interfaces: These enable the BMS to interact with external systems, such as the charger or the vehicle control system. Information is exchanged in this way to coordinate operation.

Why do you need a BMS?

The role of a battery management system (BMS) is clear enough from the tasks mentioned above. The key focus is on safety, extending battery life, optimising performance and efficiency, as well as monitoring, communication and data transmission.

Safety

In terms of safety, a BMS prevents overcharging and deep discharging. Lithium-ion cells, especially, are highly sensitive to overcharging and deep discharging. Short of a BMS, overcharging could result in overheating, fire, or even explosion.

Short circuits resulting from malfunctions can thus be avoided.

Extension of service life

By balancing the cells, the BMS guarantees consistent charging and discharging. As a result, the cells age more slowly, which in turn extends the battery's service life. Smart management of the charging process also positively influences the number of possible charging cycles.

Performance optimisation

The battery management system ensures optimal battery usage by guaranteeing that its maximum capacity is utilised efficiently. If the battery is always in optimal condition, then not only is the maximum capacity available, but also the performance in terms of the charging or discharging process.

Diagnosis

With continuous monitoring and real-time battery diagnostics, errors are detected and diagnosed in a timely manner. Any cell faults or abnormal temperature changes can be detected quickly, and suitable countermeasures can be taken.

Integration into other systems

The BMS can communicate information on the state of its own battery to other systems, such as an electric vehicle's energy management system or external chargers.

Examples - Where can you find a BMS?

In principle, a battery management system is built into all electrical devices that run on a battery or storage battery, such as in smartphones, electric cars, or even solar installations.

Electric vehicles

Electric vehicles typically utilise large batteries with many cells. A BMS is used to monitor and regulate such a system. With no BMS, the battery may age more rapidly, the vehicle's range may decrease, and safety may be compromised. A BMS is also found in electric bicycles and scooters.

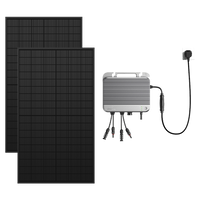

Renewable energy production

Batteries and accumulators are often used with solar installations and wind turbines in the production of renewable energy to store excess unused energy. In this case, a BMS is crucial for both protecting the battery from overcharging due to large fluctuations in energy flow and for managing electricity efficiently. Furthermore, the battery management system will ensure that the battery cells are discharged evenly, which will help to extend the battery's lifespan.

Good to know: All Zendure energy storage devices feature a smart battery management system to control and monitor energy flows.

Everyday carry devices

Smartphones, laptops, tablets and smartwatches require small, safe and lightweight batteries with a long operating life. For such devices, a BMS helps keep the battery safe, especially during intensive use, and ensures that its capacity is used to the fullest.

Industrial applications

In this context, batteries are often used to supply uninterrupted power to machines or robots. A BMS is vital in order to protect against extreme conditions. It can monitor the state of the batteries and optimise them to minimise breakdowns and reduce operating costs.

Aeronautics and aerospace

Although not obvious, a BMS is vital in the aeronautics and aerospace industries, where the reliability of batteries is crucial. It ensures that they operate reliably in extreme conditions, such as when exposed to temperature variations and vibrations. In this field, a failure can have fatal consequences, making monitoring and control by a BMS essential. In addition to drones, satellites and flying devices, space suits can also be equipped with batteries.

Medical devices

Portable heart monitors and defibrillators are two typical examples of medical devices fitted with batteries, and they too require a battery management system, as their reliability and safety are paramount. A BMS helps guarantee that batteries are always in optimal condition for reliable operation in the event of an emergency.

How does a battery work?

A storage battery or battery turns chemical energy into electrical energy by displacing electrons between two electrodes – the anode and cathode – in a controlled process. The anode is the negative electrode that frees up electrons, while the cathode, the positive electrode, absorbs them. Between these two electrodes is an electrolyte (substance) that carries ions between the anode and cathode. A separator keeps the two electrodes permanently isolated from each other to prevent short-circuiting and only allows ions to go through.

Discharge

When a battery is discharged, electrons flow from the anode to the cathode through an external electrical circuit, making a lamp shine, for example. During this time, ions inside the battery move through the electrolyte to maintain chemical equilibrium. This process releases the energy stored in the battery, which can then be used, for example, by a smartphone or an electric motor.

Charge

When a battery is being recharged, the reverse process occurs. The external electrical energy used for storage is used to reverse the chemical reaction in the battery. As a result, the battery is once again ready to store and release energy.

Conclusion: a battery management system is essential

Using a battery management system (BMS) therefore appears essential to maintain the safety, efficiency and lifespan of batteries. This system, comprised of hardware and software elements, continuously monitors the status of each battery cell, prevents hazards such as overcharging and overheating, and guarantees optimal charging and discharging.

If no BMS were used in batteries, they would age faster, operate inefficiently or even pose safety risks. In today's world, when batteries already play a central and growing role in fields such as electric mobility, renewable energy and portable electronics, a BMS is essential. It is the only way to maximise and, above all, guarantee performance and reliability.

Leave a comment